How to Conduct Value Chain Analysis (Free Templates)

If you ever look forward to adding worth to your business, consider conducting a value chain analysis (VCA) within the business.

So, what is a value chain?

Value chain is the chain of business activities carried out by your organization to create the product or service it offers – all the activities from start to finish. Value chain analysis helps you sketch out the steps that your business follows to convert raw materials or ideas into a final product or service that you deliver to your customers.

This blog will explain what is value chain analysis, explain via examples and give free value chain analysis template.

Jump straight to free value chain analysis template here.

What is Value Chain Analysis?

It is when you analyze your value chain activities.

Value Chain Analysis (VCA) is the practice of breaking down your business operations into primary and secondary activities. Value chain analysis is done to understand how these activities interact with each other and support value creation.

Value chain analysis is a process that identifies the primary and secondary activities of the business.

VCA includes every stage of the product or service’s lifecycle and the ways to optimize them.

It helps in breaking down all the activities, from acquiring raw materials to delivering the final product.

Value chain mapping helps understand the cost and effectiveness of each stage.

In short, Value chain mapping is a strategic process used to separate primary and secondary processes involved in the production of a product or service in order to carefully monitor them for cost and efficiency so that the business can benefit from profitability.

The concept of Value chain analysis was given by Michael Porter in his 1985 book “The Comprehensive Advantage: Creating and Sustaining Superior Performance.”

How to Conduct Value Chain Analysis

If you are interested in conducting a value chain analysis within your business, follow these five primary steps. Once you identify and follow these steps, identify the areas of improvement and optimize them for efficiency of activity, cost efficiency, and overall productivity of the activity.

Flow diagram of steps to conduct VCA

Effective Steps to Value Chain Analysis

Below is the description of these steps.

Pinpoint Primary Processes:

Primary processes include all the main processes involved in producing and delivering your product or service. These primary processes include:

| Column 1 | Column 2 |

|---|---|

| Primary Processes | Primary Processes |

| Inbound logistics | Receiving, storing, and distributing inputs / ideas / raw material |

| Operations | Transforming inputs / raw materials into outputs / product / service |

| Outbound logistics | Collecting, storing, and distributing finished goods |

| Marketing and sales | Promoting and selling products or services |

| Service | Providing after-sales support |

Separate Secondary / Support Processes

These are the processes that work to support the primary processes of your organization. Some of the key secondary processes are:

| Column 1 | Column 2 |

|---|---|

| Secondary Processes | Secondary Processes |

| Procurement | Acquiring raw materials / inputs |

| Human Resource Management | Recruiting, training, and developing employees |

| Technology Development | Developing and maintaining technology |

| Infrastructure | Supporting the overall operations |

Find Out the Value Contribution of Each Activity

Now that you have separated the processes, it’s time to evaluate them. Evaluate how each activity supports the product value and whether it provides a competitive advantage to your organization or not.

Analyze Costs and Benefits of the Activities

Assess the cost-effectiveness of each activity and identify where improvements can be made.

Identify Areas of Improvement

Look for inefficiencies or possible opportunities for strategic improvement that could result in low costs and more value.

Value Chain Analysis Template

A value chain analysis template helps you map out and visualize your organization’s activities. A standard value chain analysis template includes columns for each primary and secondary activity alongside sections to note value contribution, costs, and opportunities for improvement.

Below is a value chain analysis template to help you understand how to sheet out the analysis.

Here’s the information formatted as a table:

Below is the simplest value chain analysis sample template to analyze the cost-effectiveness and value contribution of each activity to help you sort out the activities.

I hope by now you understand how to segregate the value chain activities of your organization and how to work to optimize them.

Value Chain Analysis Example

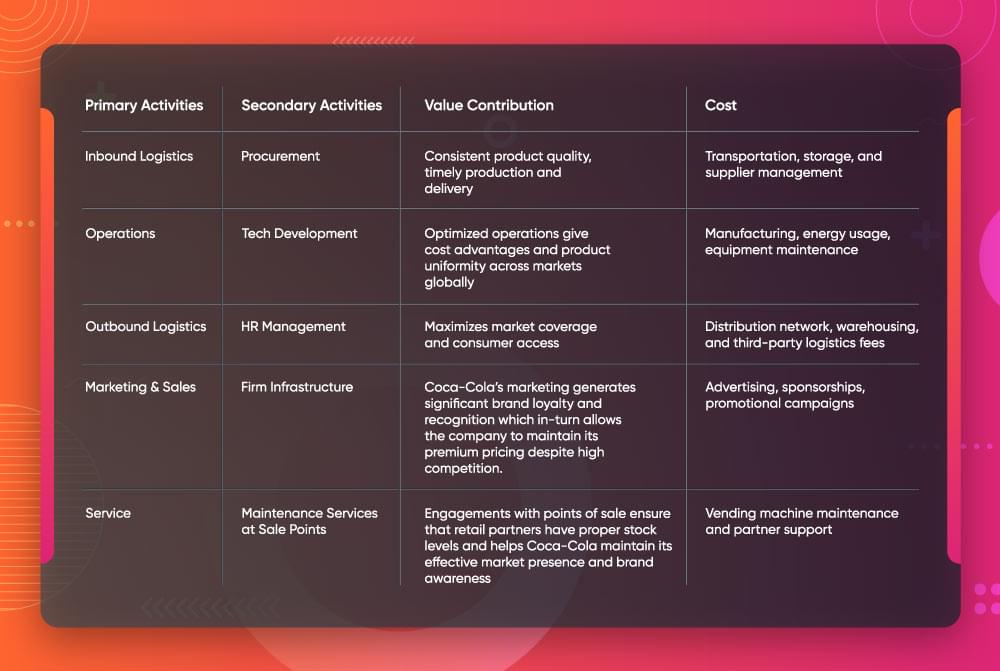

Let’s take the case of Coca-Cola’s value chain mapping and understand how it has helped the company.

Coca-Cola’s Primary Processes:

Coca-Cola’s primary activities in its value chain focus on the core operations. These operations directly add to creating and delivering its beverages to consumers. These processes include:

Inbound Logistics:

Coca-Cola sources raw materials like water, sweeteners, flavor concentrates, and packaging materials (bottles, cans, labels). The company manages its relationships with different suppliers all over the world and works on optimizing the delivery of these resources to its manufacturing plants.

Operations:

Coca-Cola operates worldwide to produce concentrates and syrups that it then distributes to bottling partners. In the bottling process, the concentrate is added to the final beverage, which is then packed and delivered.

Outbound logistics:

Once bottled, Coca-Cola products are distributed to retailers, wholesalers, and directly to restaurants, vending machines, and other points of sale. The company has a highly efficient distribution network. This network uses both company-owned and third-party logistics partners.

Marketing & Sales

We already know that Coca-Cola is known for its massive marketing and advertising campaigns. Its marketing and sales teams focus on building brand awareness via traditional media, digital marketing, social media campaigns, and sponsorships of major events like The Olympics.

Service (After-Sale):

Since Coca-Cola’s products are consumable, the company does not have much to do with after-sale services. However, the company does engage with retailers and restaurants, etc, in activities like service and maintenance of vending machines to make sure their product is properly handled and distributed.

Coca-Cola’s Secondary Processes

The secondary or support processes in Coca-Cola’s value chain make sure the efficiency and effectiveness of primary activities. These include:

Procurement

Coca-Cola’s procurement involves sourcing raw materials. The company keeps extended relationships with its suppliers and uses bulk purchasing to reduce costs.

Technology Development:

To improve its production processes, Coca-Cola invests heavily in technology development. These automated production processes then help to improve products and their packaging styles and designs. Innovations include lightweight bottles and cans, new flavors, and packaging technology like PlantBottle TM.

Human Resource Management:

The HR management of Coca-Cola recruits top talent. They have a highly optimized hiring system that chooses best employees for the company. Coca-Cola keeps a strong corporate culture.

Firm Infrastructure:

Coca-Cola’s firm infrastructure includes its finance, legal, management, and strategic planning operations. The company has a robust global management system that allows it to operate efficiently in different markets while maintaining a strong global brand.

Value Contribution of Each Activity

Let’s take a brief look at what values these activities bring to the company.

Inbound Logistics: consistent product quality, timely production and delivery

Operations: optimized operations give cost advantages and product uniformity across markets globally.

Outbound Logistics: maximizes market coverage and consumer access.

Marketing & Sales: Coca-Cola’s marketing generates significant brand loyalty and recognition, which then allows the company to maintain its premium pricing despite high competition.

Service: Engagements with points of sale ensure that retail partners have proper stock levels and help Coca-Cola maintain its effective market presence and brand awareness.

Procurement: reduced material costs and a steady supply of raw materials.

Technology Development: technological innovations improve production efficiency, reduce costs, and better product quality.

HR Management: we know that a motivated employee or workforce always adds to the long-term growth of the company

Firm Infrastructure: strong firm infrastructure helps manage complex international operations with compliance with company regulations and corporate governance standards.

Cost and Benefit Analysis of Each Activity

Inbound Logistics:

Cost: Transportation, storage, and supplier management.

Benefit: Uninterrupted supply of quality raw materials leads to uninterrupted production of the beverage.

Operations:

Cost: Manufacturing, energy usage, equipment maintenance.

Benefit: Mass production at lower costs, product uniformity, and scalable operations.

Outbound Logistics:

Cost: Distribution network, warehousing, and third-party logistics fees.

Benefit: Wide product availability, quicker time-to-market, and enhanced consumer access.

Marketing & Sales:

Cost: Advertising, sponsorships, promotional campaigns.

Benefit: Strong brand recognition, consumer loyalty, and the ability to command premium prices.

Service:

Cost: Vending machine maintenance and partner support.

Benefit: Ensures consistent product availability and reinforces the brand’s market presence.

Identify Areas for Improvement

Sustainability in Packaging:

Coca-Cola has been criticized for the use of plastic bottles many times since plastic bottles increase environmental pollution. Investing further in biodegradable packaging solutions and taking initiatives like PlantBottle™ could improve brand image and reduce environmental impact from plastic.

Water Usage:

Coca-Cola’s operations involve a lot of water in production. But in areas where there is less water, it becomes difficult to meet the demand. The company needs to continue funding water conservation and purification projects so that environmental concerns are addressed and operations are uninterrupted.

Cost Efficiency in Supply Chain:

Changing costs of raw materials effect profitability. But if more suppliers are added and supplier contracts are extended to longer durations then this matter can be resolved.

Digital vs Traditional Marketing:

Traditional marketing styles like billboard ads near highways have always been a part of Coca-Cola’s marketing strategy but digital platforms are more effective.

Increasing investment in digital marketing should bring better results because it targets the right customers.

New and Creative Product Line:

Over the years, people have become more health conscious, and so their tastes have shifted to consuming healthier beverages. Coca-Cola can continue to innovate by expanding its image of low-calorie and sugar-free beverages to capture emerging health-conscious markets.

This sample value chain analysis for Coca-Cola highlights how each part of the company’s operations contributes to its overall success. We saw how VCA identified those areas in the system where improvements could increase efficiency, sustainability, and competitiveness.

What Is a Global Value Chain?

A global value chain (GVC) is a value chain in which the steps and operations needed to launch a product take place across multiple countries.

Conclusion

Keeping in mind this well-structured value chain mapping that allows Coca-Cola to maintain product quality and brand image worldwide. I hope performing similar activities for any business will not be as difficult and that the concept is clear now.

Related Reads: